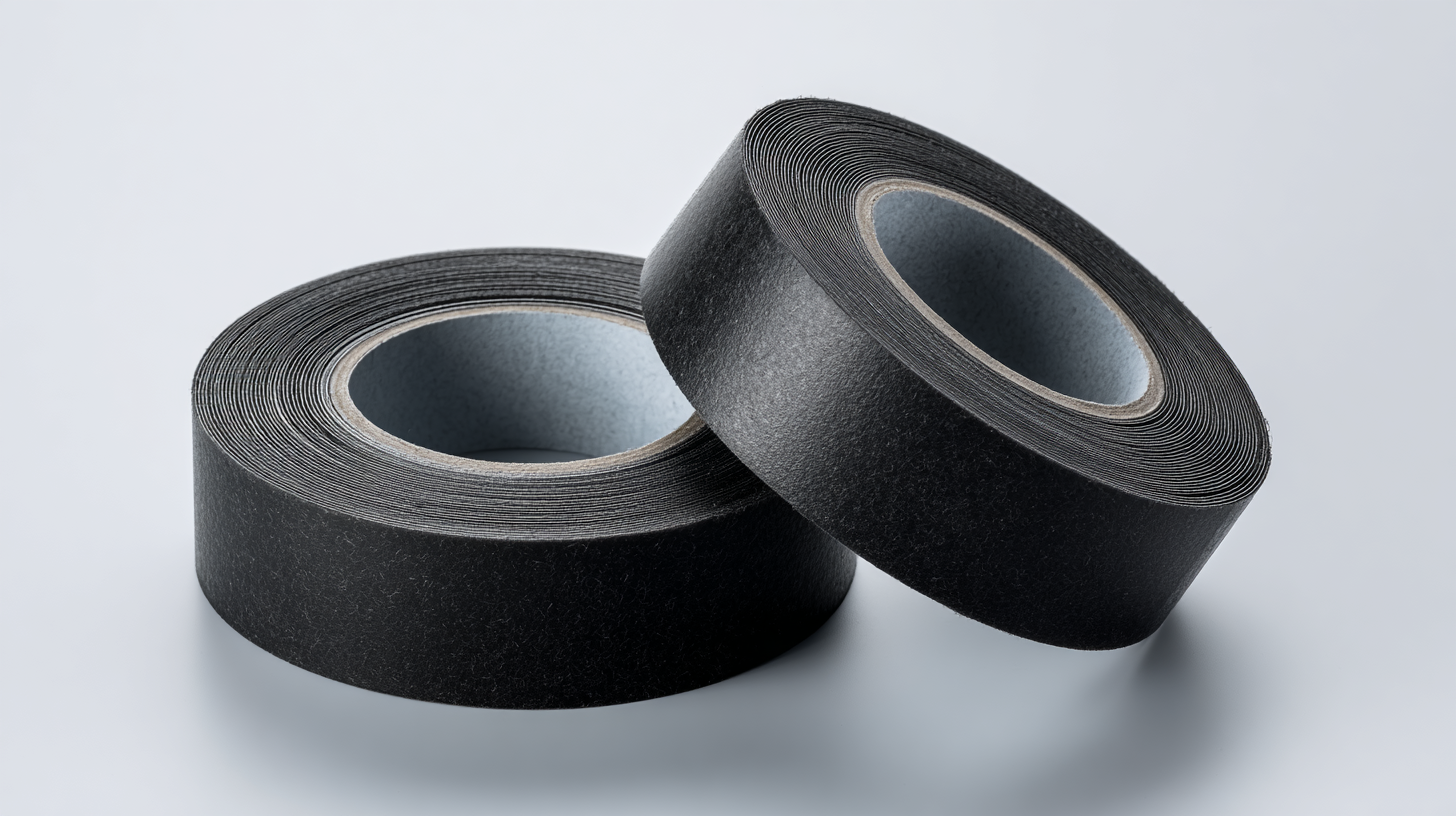

In the realm of construction and DIY projects, the selection of materials plays a pivotal role in achieving optimal results, with Double Tape Rubber emerging as a favored choice among professionals and enthusiasts alike. According to a report by Smithers Pira, the global adhesive tape market is projected to reach $68 billion by 2025, with double-sided tapes capturing significant market share due to their versatility and efficient bonding capabilities.

This remarkable growth can be attributed to the increasing demand for high-performance materials across various sectors, including automotive, packaging, and electronics. Choosing the right Double Tape Rubber is essential for ensuring durability and effectiveness in applications ranging from mounting and repairs to crafting and insulation.

As we delve into the ultimate guide for selecting the best Double Tape Rubber for your projects, it is crucial to consider factors such as adhesion strength, thickness, and environmental resilience to achieve the best outcomes.

Choosing the right double tape rubber is essential for success in various projects, particularly in sectors that demand precise adhesion and durability. The significance of selecting the right type cannot be overstated, as it directly impacts the quality of the final product.

According to industry reports, the rubber processing market is projected to grow at a rate of 3.94% from 2024 to 2031, indicating a rising demand for high-performance materials, including double tape rubber. This growth highlights the increasing reliance on quality adhesive solutions across different applications.

In specialized industries such as construction, automotive, and electronics, the type of double tape rubber used can determine the durability and functionality of assemblies. With an estimated market size of $2,198.10 million for rubber craft oils in 2023, the focus on selecting the appropriate adhesive materials aligns with the larger trends within the sector.

Therefore, understanding the unique requirements of each project and choosing the right tape can lead to enhanced performance and longer-lasting results, ultimately contributing to business success and customer satisfaction within these competitive markets.

When choosing the best double tape rubber for your projects, it’s essential to understand the key features that can make a difference in performance and durability. Look for types with strong adhesive properties, as this ensures a secure bond between surfaces. Opting for rubberized tape that can withstand various temperatures and conditions is also essential, especially for outdoor projects or applications in fluctuating environments.

Another critical factor to consider is the thickness of the tape. A thicker double tape rubber often offers better cushioning and support, making it ideal for heavy-duty applications. Additionally, consider the tape's resistance to moisture and chemicals, as this can greatly enhance its lifespan and functionality in different settings.

**Tips:** Always test a small section before applying it extensively to ensure that the adhesive will not damage the surfaces involved. Also, consider the ease of removal; some tapes are designed to leave minimal residue, which can be beneficial for temporary applications or for projects where the tape may eventually need to be taken off.

When selecting the best double tape rubber for your projects, understanding the quality and performance of various brands is essential. Popular brands such as 3M, Scotch, and Gorilla each offer unique features that cater to different needs. 3M double-sided tapes are renowned for their superior bonding strength and durability, making them ideal for heavy-duty applications. Their innovative technology also ensures a clean removal without residue, which is particularly beneficial for temporary installations.

On the other hand, Scotch double tape rubber is known for its versatility and ease of use, making it a favorite for crafting and home improvement tasks. It provides good adhesion on various surfaces while still being user-friendly. Gorilla, while newer to the market, has quickly gained traction for its robust adhesive properties and weather resistance, suitable for outdoor projects. By comparing these brands, you can make an informed decision tailored to the specific requirements of your project, ensuring optimal results every time.

When undertaking DIY projects, the effective application of double tape rubber can significantly enhance both functionality and aesthetics. According to a report by the Adhesive and Sealant Council, the right tape can increase bond strength by up to 50%, making it an essential tool in crafting and repairs. To maximize its efficacy, ensure that the surfaces are clean and dry before application, as contaminants can weaken the adhesive bond.

In addition, employing the correct technique when applying double tape rubber is crucial. Experts recommend using a firm, even pressure to activate the adhesive fully, and considering environmental factors such as temperature and humidity. The 2023 Global Adhesives Market Report highlighted that temperatures above 70°F (21°C) yield optimal adhesion, as colder conditions can impede the adhesive's performance. For intricate projects, cutting the tape into smaller strips can help achieve precision without compromising the bond's integrity. Following these application tips can lead to a more successful and durable finish on your DIY projects.

When choosing double tape rubber for various projects, many individuals fall into common pitfalls that can significantly hinder the effectiveness of their work. One frequent mistake is overlooking the importance of adhesion strength. According to a report by the Adhesive and Sealant Council, the right adhesive selection can enhance project durability by up to 50%. Therefore, it's crucial to assess the materials being bonded and their respective surface conditions before making a choice.

Tip: Always test the tape on a small surface before full application to ensure optimal adhesion and compatibility.

Another common error is ignoring environmental factors such as temperature and humidity. Studies indicate that double tape rubber exposed to extreme conditions can lose up to 30% of its adhesive capabilities. Understanding the working environment can help in selecting a tape formulated to withstand specific conditions, thus preserving its performance.

Tip: Opt for tapes specifically designed for your project’s environmental conditions to avoid unexpected failures.

By being mindful of these mistakes and implementing these tips, you can significantly improve the outcome of your projects.

| Feature | Importance | Common Mistakes | Tips for Selection |

|---|---|---|---|

| Adhesive Type | High | Choosing wrong adhesive for materials | Match adhesive to project materials |

| Thickness | Medium | Ignoring thickness requirements | Consider load and material characteristics |

| Temperature Resistance | High | Neglecting environmental conditions | Check temperature limits for usage |

| Stickiness | High | Overestimating required stickiness | Test stickiness on sample materials |

| Durability | High | Choosing low-quality options | Research material strength and longevity |

| Ease of Use | Medium | Forgetting application methods | Read application instructions carefully |