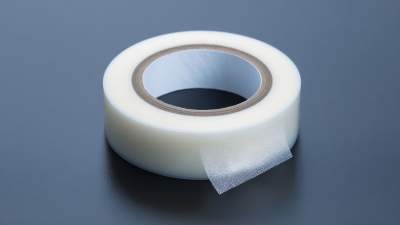

In today's competitive landscape, selecting the right materials for your business can significantly impact productivity and efficiency, particularly when it comes to adhesive solutions like Double Tape Rubber. According to a report by MarketsandMarkets, the adhesive tapes market is projected to reach $63.2 billion by 2025, with a notable increase in demand for double-sided tapes across various industries, including automotive, electronics, and packaging. Businesses continuously seek ways to enhance adhesion performance while reducing costs, making the choice of double tape rubber an essential consideration. With various options available, it is crucial to understand the critical factors that influence effectiveness and suitability for your specific needs. In this blog, we'll explore five essential tips to help you navigate the selection process and ensure you choose the best double tape rubber for your business requirements.

When selecting the best double tape rubber for your business needs, it's crucial to understand the various types available in the market. Double-sided tape can be categorized mainly into pressure-sensitive adhesive (PSA) types, with key differences in materials like acrylic and rubber. Each type offers unique benefits, making it essential to choose based on your specific application requirements.

When it comes to selecting the right double tape rubber for your business, evaluating adhesive strength is crucial. According to a report by the Adhesive and Sealant Council, the performance of adhesive products can vary significantly, with some tapes offering shear strength ratings up to 50 PSI. This variance means that understanding your specific application’s demands is necessary to select a tape that won’t fail under pressure.

Tip 1: Assess the surfaces you intend to bond. Different materials, such as metal, plastic, or foam, interact differently with adhesives, which can affect the overall bond strength. For instance, if you are bonding foam to a hard surface, look for a tape with a higher tack and initial adhesion.

Furthermore, it's vital to account for environmental factors. A study by 3M found that temperature fluctuations and humidity can reduce the effectiveness of adhesive bonds.

Tip 2: Test adhesive products in real-world conditions whenever possible. Opt for tapes that specify their performance across a range of temperatures and moisture levels, ensuring they can withstand the environment in which they will be used. This can prevent costly failures and enhance operational efficiency. Understanding these elements will empower you to make informed decisions that align with your business's unique needs.

| Adhesive Type | Application Surface | Adhesive Strength (N/cm) | Temperature Resistance (°C) | Recommended Use |

|---|---|---|---|---|

| Acrylic | Metal | 12 | -40 to 80 | Outdoor Signage |

| Rubber | Plastic | 15 | -10 to 60 | Automotive Assembly |

| Silicone | Glass | 10 | -50 to 150 | High-Temperature Applications |

| Viscoelastic | Wood | 8 | 0 to 70 | Mounting Items |

| Polyester | Concrete | 20 | -20 to 50 | Heavy Duty Applications |

When selecting double tape rubber for business applications, durability should be a primary consideration. According to a report by the Adhesive and Sealant Council, the demand for high-performance rubber tapes is expected to grow by 5% annually, driven by advancements in materials and adhesive technologies. Businesses must understand that not all rubber tapes are created equal; key factors affecting durability include the rubber type, adhesion strength, and environmental resistance.

Natural rubber, for instance, offers excellent elasticity but may degrade with exposure to UV light and moisture. In contrast, synthetic rubbers such as neoprene and nitrile provide superior resistance to temperature fluctuations and chemicals, significantly extending their lifespan in demanding environments. A study by the American Society for Testing and Materials highlights that tapes made from synthetic rubbers can last up to three times longer than their natural counterparts when applied in outdoor conditions. By evaluating these characteristics and aligning them with specific operational needs, businesses can make informed choices that enhance productivity and reduce costs.

When selecting double tape rubber for your specific applications, temperature resistance is a crucial factor to consider. According to a recent industry report by the Adhesive Tape Manufacturers Association, tapes designed for high-temperature environments can withstand temperatures ranging from 350°F to 500°F (about 177°C to 260°C). This is particularly important for industries such as automotive and aerospace, where materials are often subjected to extreme conditions. Understanding the temperature range your application will face can guide you in selecting the most suitable tape.

When evaluating double tape rubber, it is also essential to consider adhesive strength and compatibility with the materials you are working with. For example, choosing a tape with an adhesive designed for rubber substrates can significantly enhance bonding performance under various temperatures. Remember, it's not just about the tape being durable; it's about how well it adheres throughout its lifecycle.

Lastly, always run adhesion tests under real-world conditions to ensure reliability. Keep in mind that even the best tape can fail if not properly tested in the actual environment it will be used in, as environmental factors can hugely influence performance. Make sure to check the manufacturer's technical data sheets to assess how the tape performs under varying temperatures.

When it comes to selecting double tape rubber for your business needs, the balance between cost and quality is paramount. According to a report from Smithers Pira, the global adhesive tape market is expected to reach nearly $80 billion by 2025, indicating a significant growth spurred by an increasing demand across various industries. However, businesses often face the challenge of choosing between cheaper options and high-quality products that may come at a premium price.

To make informed purchasing decisions, it is crucial to first assess your specific application requirements. Here are some helpful tips:

1. Evaluate the bonding strength needed for your application. For example, high-performance double tape rubber products may offer superior adhesion necessary for industrial uses, while lighter options may suffice for general purposes.

2. Consider the environmental conditions where the tape will be used. Some products perform best in extreme temperatures or humid environments. According to the Adhesives and Sealants Industry report, choosing the right tape can reduce the risk of failures, leading to lower overall costs.

Ultimately, investing in quality double tape rubber may yield better long-term benefits, such as durability and reduced maintenance costs. Prioritizing quality over short-term savings can enhance your operational efficiency, as supported by a study from the American Institute for Packaging and the Environment, which highlights the importance of tape integrity in packaging solutions.